Da anni Beinat è il compagno di fiducia della tua azienda: i suoi prodotti sono garantiti al 100% e la sua affidabilità permette un turn over costante all’interno del tuo magazzino. Lo studio sul prodotto singolo permette di ottenere apparecchiature all’avanguardia in grado di far fronte a tutte le esigenze: dalla realizzazione di un sistema antincendio alla termoregolazione, sino alla sicurezza gas.

Beinat SRL

Sicurezza ed efficienza impiantistica al tuo servizio

Beinat S.R.L. nasce nel 1978 a Ciriè, in provincia di Torino, dopo un’esperienza di circa 5 anni.

In 40 anni la passione per l’elettronica e la capacità di proporre sempre prodotti innovativi e all’avanguardia, hanno fatto di Beinat un’azienda di primo livello nel settore della sicurezza gas a uso civile, delle centraline, sonde gas, termoregolazione, sonde e impianti antincendio e molto altro ancora.

Dallo studio alla creazione del prodotto

Il cuore pulsante della Beinat

I nostri ingegneri a tua disposizione: tutta la progettazione parte da zero, dall’identificazione di un bisogno all’ideazione di un prodotto. Le idee dei clienti sono il punto di partenza di ogni cosa. Design e innovazione sono le parole chiave.

Prodotti in evidenza

Ricerca e sviluppo per fornire prodotti innovativi

La gamma Beinat soddisfa le esigenze più disparate, spaziando dal semplice termostato per termoregolazione fino alle apparecchiature per la sicurezza gas a uso civile (come i rilevatori di fughe di gas), sonde, dispositivi antincendio e accessori.

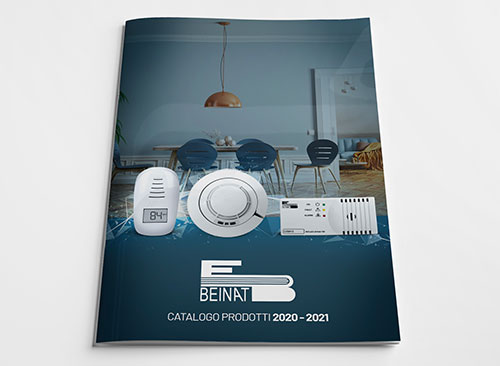

Catalogo

Tutti i prodotti Beinat

Innovazione e affidabilità sono le parole che descrivono il nostro nuovo catalogo.

Qui troverai tutti i dettagli dell’azienda, il motivo per cui ci teniamo tanto a fare quello che facciamo e tutto quello che c’è da sapere sui nostri apparecchi.

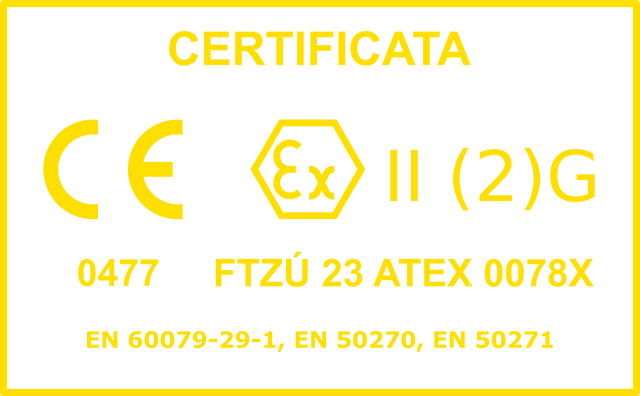

Le nostre certificazioni di qualità e garanzia

L’importanza della politica per la qualità

Da sempre l’obiettivo è quello di fornire prodotti rispondenti alle esigenze del cliente, attraverso un miglioramento costante delle prestazioni e con un impegno a 360°.

#AmiCOaroundtheworld

Il tuo AmiCO contro il monossido di carbonio

Un AmiCO piccolo, ma pronto a proteggerti ovunque.

Meno di 60 grammi di peso, subito attivo e operativo perché non ha bisogno di installazione, dotato di batteria e sensore di lunga durata, totalmente Made in Italy: AmiCO è il rilevatore gas domestico che segnala la presenza di monossido di carbonio in casa e ti accompagna… in tutto il mondo!

News

Tutto sulla sicurezza per la tua casa o azienda

Beinat Srl

Gas solutions

Via Fatebenefratelli, 122/C

10077 San Maurizio Canavese

Torino – Italia

Tel. +39 011 92 10 484

Fax +39 011 92 11 477